and Seal Solutions

What's At Stake? Everything.

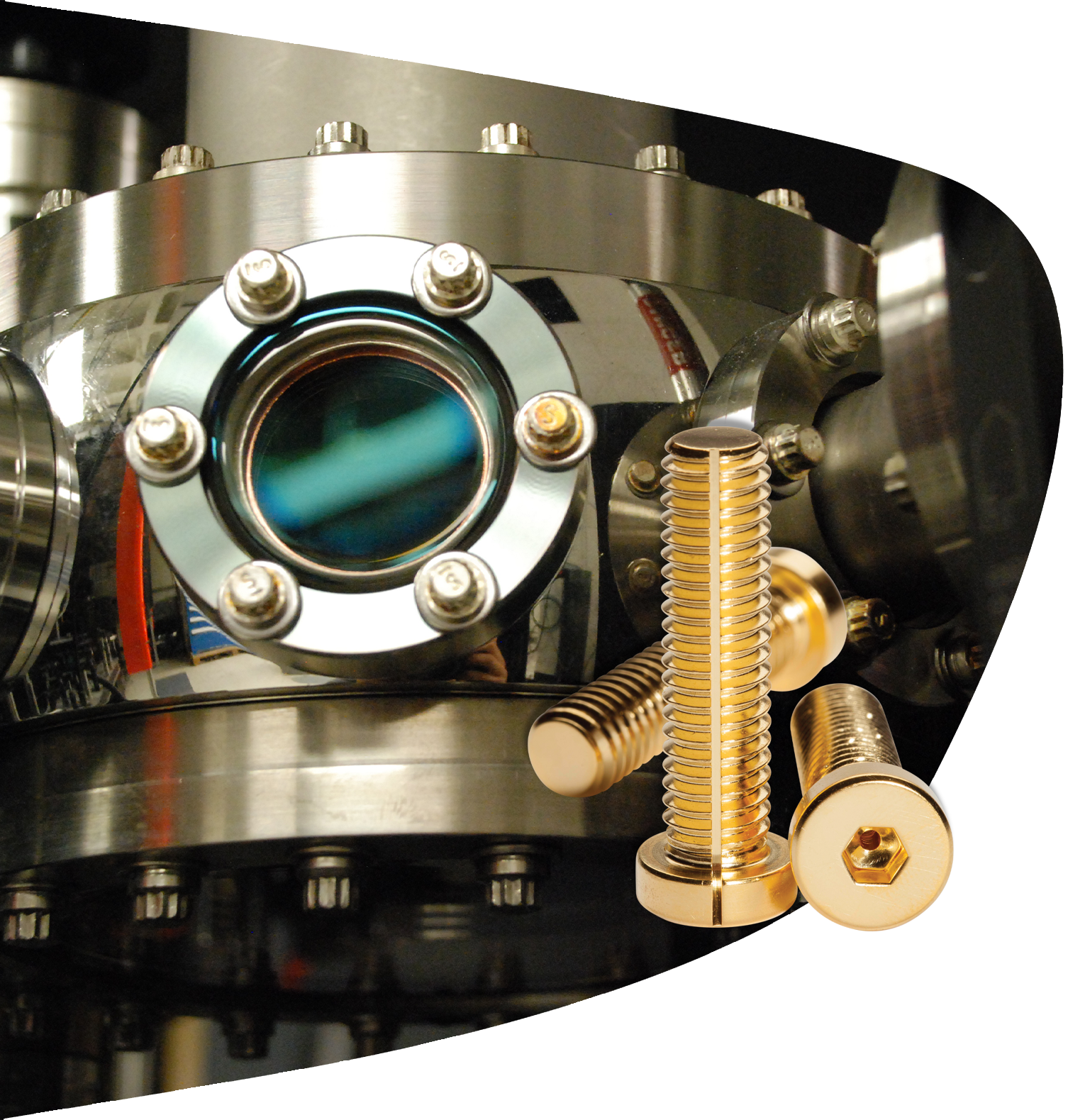

Vacuum Processing is required for achieving pure manufacturing environments in a wide variety of industries, from semiconductor manufacturing for smart phones to photovoltaics for rooftop solar panels to optics for laser devices and even sunglasses.

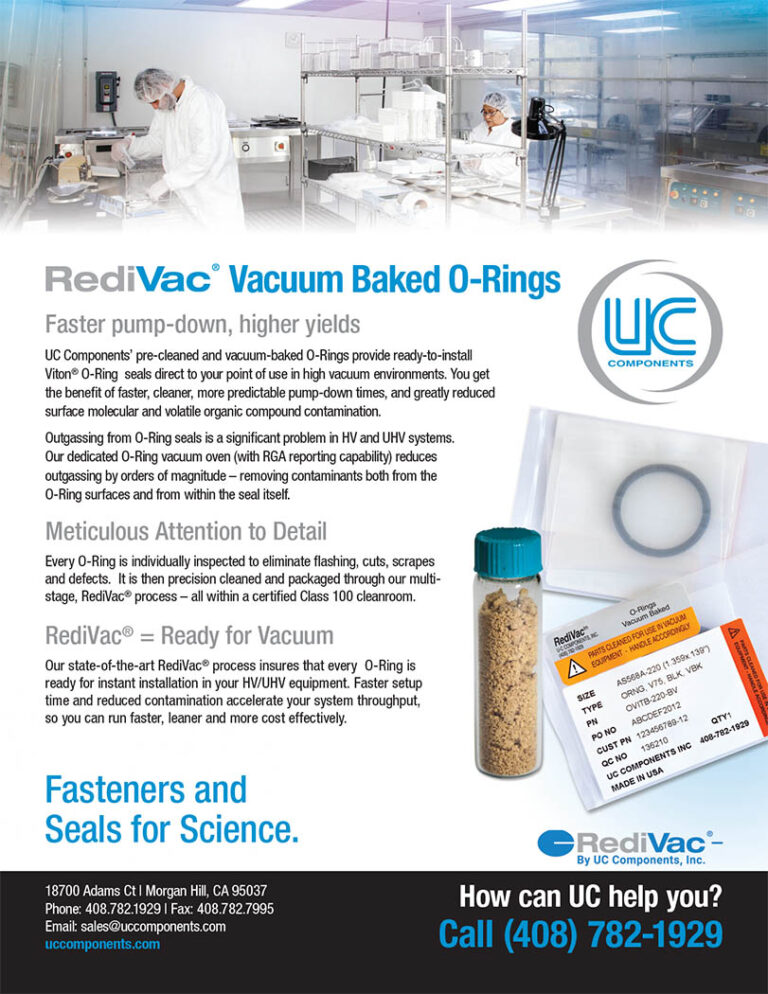

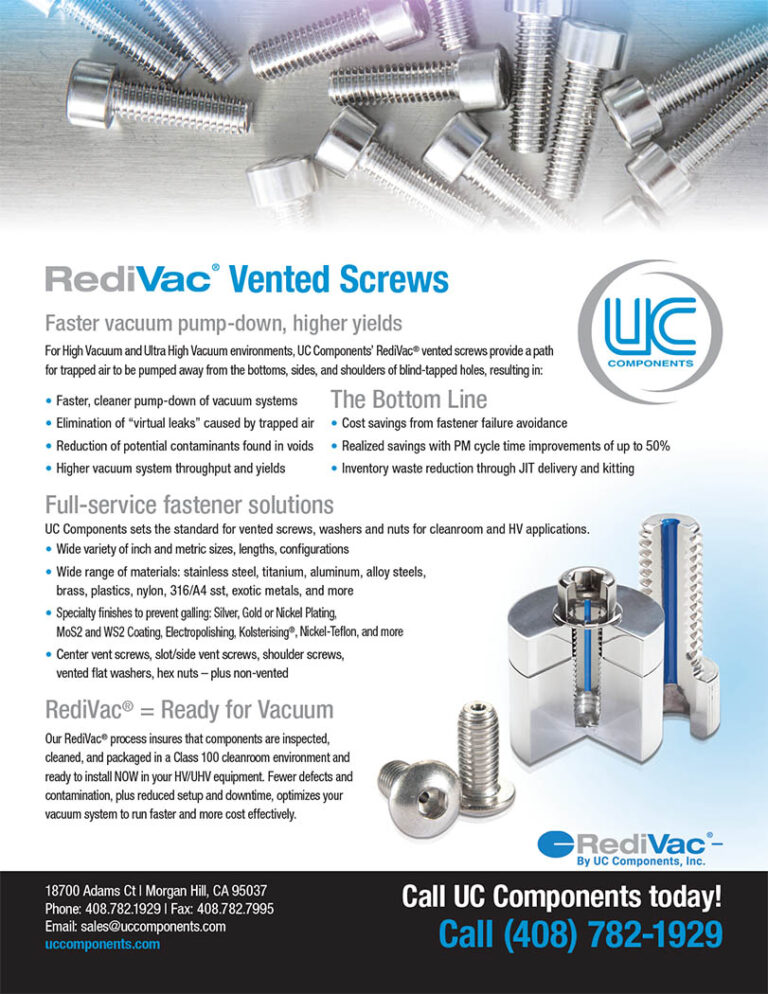

From high vacuum (HV) to ultra-high vacuum (UHV) applications, UC Components, Inc. RediVac® line of fasteners and seals helps vacuum systems perform better through faster, cleaner pump-down. Reduced outgassing from our cleaned and vacuum-baked O-rings, the elimination of virtual leaks from our vented vacuum screws, and minimized parts maintenance (PM) change times through the eradication of fastener galling (seizing) are among the benefits of the RediVac® product line.

We deliver solutions – vented, plated, polished, inspected, and clean room-ready – exactly as promised.

Guaranteed.

Critical Applications

RediVac® means ready for all vacuum applications.

Specified quantities for custom maintenance evolutions.

Special surface treatments to prevent Galling.

Coatings for better adhesion.

The right part, for the right application, right when you need it.

Part Traceability

From print to installation, every part is fully traceable, down to the last screw.

Quality Control

UC’s obsessive attention to detail comes from a fierce commitment to your success.

Application Expertise

Our Certified Fastener Specialists™ are experts in your industry, and available to solve your problem now.

Don’t know what you need?

Our specialists do, and will guide you.

1. Call a UC Engineer

2. We Review & Spec

3. Problem. Solved.

Resources & Content

Navigating the Skies: A flawed fastener can make or break your mission

A recent article about NASA opening a canister containing material...

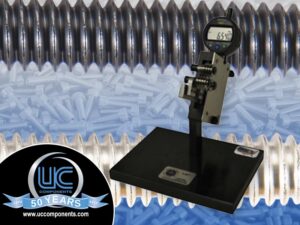

Read MoreUC Components, Inc. Introduces New Cutting-Edge X-120 Adjustable Tri-Roll Thread Gage for More Precise Fastener Measurement

UC Components, Inc. proudly announces the acquisition and implementation of...

Read MoreWhy are dowel pins used in clean-critical industries?

UC Components, Inc. takes pride in offering a comprehensive range...

Read MoreRolled vs Cut Fastener Threads – Which is better for your application?

Fastener manufacturing is a multi-step process that includes (in a...

Read More