Product packaging is both an art and a science – designed to look attractive while properly storing, containing, and protecting the products inside. We all know that packaging performs a pretty basic function and it may seem like a minor component however, when it comes to clean-critical applications, the package your parts come in can mean the difference between success and failure.

Beyond the basic marketing and aesthetic purposes associated with all product packaging there are three main things packaging does for critical applications:

- Storage – It provides an appropriate container to hold the product while in storage or transportation.

- Protection – The packaging protects the contents from external, potentially damaging, influences such as oxygen, dust, sunlight, electrostatic discharge, mechanical shock, vibration, moisture, breakage, and more.

- Information & Identification – The packaging provides detailed information about the contents including the name, part number, lot number, materials, manufacturing date, guidelines for use, and more.

Fasteners, such as bolts and screws, are needed in virtually every clean-critical machine and their effectiveness is a key consideration when assembling any type of machinery. Every part that goes into a clean-critical environment, such as a vacuum chamber, needs to be completely free from surface contaminants, volatile materials, moisture, gases and other contaminants trapped in the parts.

The proper handling and packaging of hardware and fasteners for your vacuum applications cannot be taken lightly. The value of a cleaned & vacuum-baked O-Ring and a properly vented screw, nut, or washer correctly packaged for immediate use may seem trivial but the overall performance and savings for you (both in cost and time) can be measured.

How does UC Components, Inc. handle packaging their fastener and o-ring products?

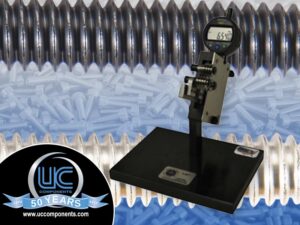

UC Components utilizes a proprietary cleaning and packaging process known as RediVac®. This process reduces surface particulates and other contamination by utilizing a multi-stage cleaning, inspecting, and packaging system which is all done inside of our top-of-the-line certified Class 100/ISO Class 5 Cleanroom.

Step 1: Ultrasonic cleaning process

Step 2: Close inspection

Step 3: State-of-the-art vacuum packaging

Inquire for RediVac® cleaning, packaging, and labeling specifications.

By reducing additional vacuum preparation steps, our RediVac® products help you run faster and leaner. RediVac® means ready for vacuum service, now! On top of our standard RediVac® packaging we also offer custom bagging and labeling options, custom cleaning, custom hardware kits, and much more.

We are always here to help you!

Since 1974 UC Components, Inc. has been known for providing fastener and seal products dedicated to improving performance and integrity of vacuum systems and other clean-critical environments. Our proprietary RediVac® system guarantees that your fasteners and seals arrive ready to install in your HV, UHV, or EUV system immediately.

For detailed cleaning, packaging, and labeling specifications and options please contact your UC Components, Inc. salesperson.

View our parts catalog online to find the components you need, request a quote, or contact us for more assistance and additional information.